Cylindrical locks and mortise locks are common and typical pieces of hardware we use on almost every project. The problem is that they can be confusing and difficult to understand on a cutsheet or even straight of the box, let alone the parts and pieces that make up these devices. Some parts are the same between the two types of commercial locksets and others are different, making it even more tricky. The other problem is hardware uses its own language that sometimes not everyone is familiar with so it can make installing or troubleshooting issue difficult. Follow along as we break down the parts of a lock for both cylindrical and mortise locks.

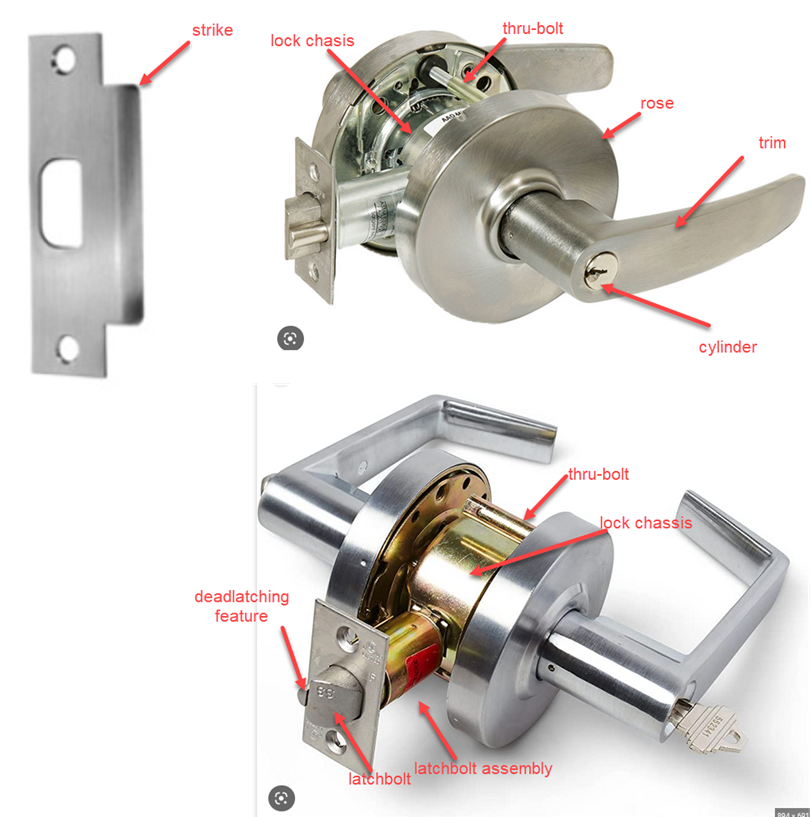

What is a Cylindrical Lock?

A cylindrical lock is a type of bored lock. The term bored refers to the prep in the door, meaning, the hole for the lock is bored through the door. Cylindrical locks come in grade 1, 2 and 3 but have limited functions in comparison to a mortise lock. Typically, cylindrical locks will be more cost effective than mortise locks but not as durable. A cylindrical lock has a cylindrical case or chassis to which the operating trim and a sperate latchbolt attaches. When you apply pressure to the trim it engages the retractor in the chassis which in turn, retracts the latch bolt. Which is a fancy way of saying when you pull the lever down it allows the internal parts to turn over and pull the latch back and allows you to open the door.

Parts of a Cylindrical Lock

- Trim-the levers or knobs used to operate the locks.

- Pushbutton– push/turn button on the inside trim to lock or unlock the outside trim.

- Rose– the decorate or protective plate, either a disk, oval or square, placed behind the trim of a lockset.

- Cylinder– the part of a lock that receives the key, this is located inside the lever or knob. When the correct key is inserted the matching keyway the pins in the tumbler mechanism algin allowing the key to turn.

- Latchbolt -the component of a lock which projects from the lock front and has a beveled end. The bolt is spring loaded but can be drawn back by operating the lock trim. When the door is closed, the latchbolt projects into a hole in the strike, which holds the door in a closed position.

- Latchbolt assembly-the assembly that houses the latchbolt and connects it to the lock.

- Lock Chassis-the part that encloses the body of the lock.

- Thru bolts-mounting post that help align both sides of the lock and secure the lock to the door.

- Deadlatching Feature– the auxiliary deadlatch portion of a two-piece latchbolt. When the door is closed, the deadlatch portion is pressed against the strike, and prevents the latchbolt from being pushed in by end pressure. Latchbolts with this feature (normally lockable functions) are called Deadlocking Latchbolts.

- Strike– a metal plate mounted to the door frame, or inactive leaf of a pair of doors, to receive the projected bolt or latch of a lock. Standard commercial strikes are typically 4 7/8”.

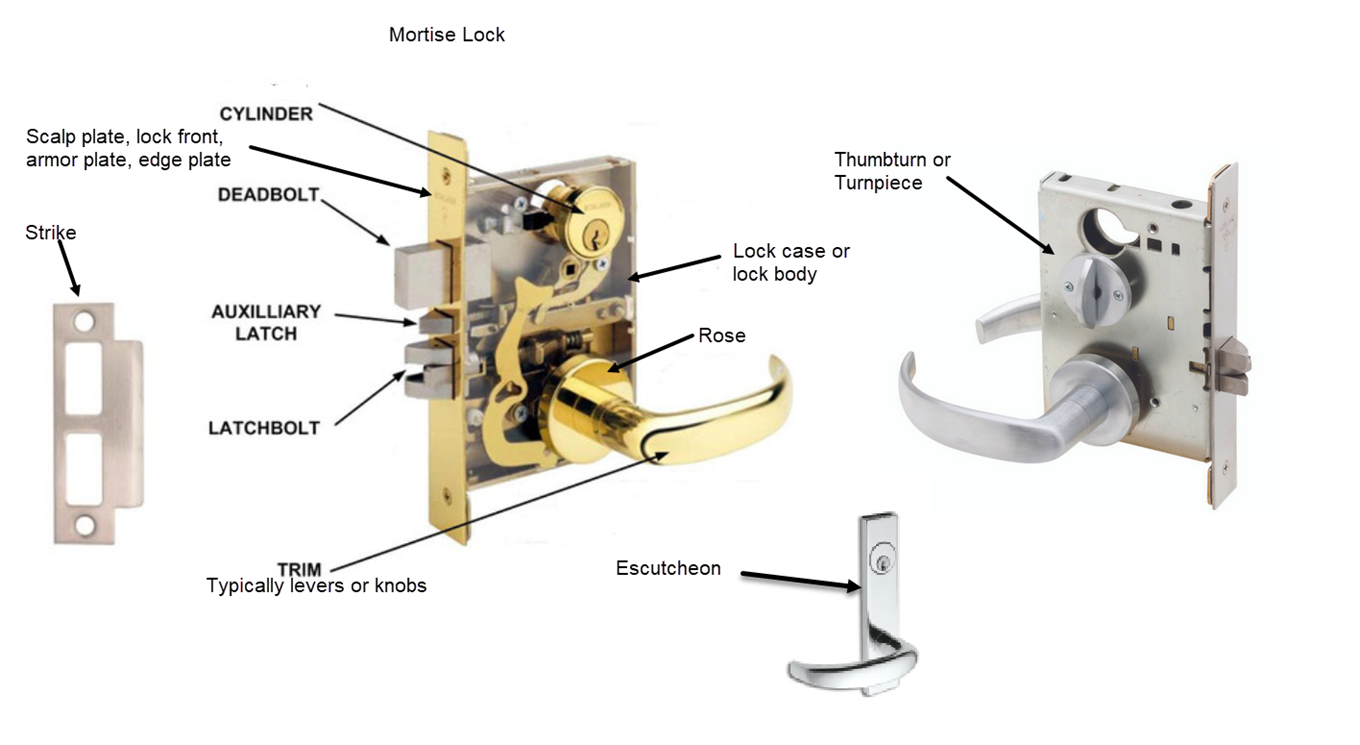

What is a Mortise Lock?

A mortise lock is assembly designed to be installed into a mortise(hole) in the edge of a door that sits 4” deep into the door, 6” high and 1” wide, and has an 8” edge plate mounted on the stile of the door. If the mortise lock has a deadbolt, it will be mounted above the trim controls the outside lever and because they are mounted separately more complex functions are available in mortise locks. Also in this case, the locking portion is mounted separate from the trim creating two latch points. This means the strike will have two openings to accept both latches. Mortise locks are much more heavy duty and will take more abuse but are not measured on a grade scale like cylindrical locks. They are more expensive because they are a more sustainable device. Mortise lock preps also vary from manufacturer to manufacturer, so its important to use the provided template to prep the door to ensure the preps are in the right place.

Parts of a Mortise Lock

- Trim-the levers or knobs used to operate the locks.

- Thumbturn– an oval or crescent shaped knob/lever used to project a deadbolt or lock the outside trim.

- Rose-a decorative or protective plate placed behind the trim, on mortise locks, rose trim and the trim around the cylinder are separate and therefore are known as Sectional Trim.

- Escutcheons -decorative or protective plate placed behind the trim are typically oblong and cover the area behind trim as well as the cylinder and thumbturn area.

- Cylinder– the part of a lock that receives the key, this is located inside the lever or knob. When the correct key is inserted the matching keyway the pins in the tumbler mechanism algin allowing the key to turn.

- Latchbolt-the component of a lock which projects from the lock front and has a beveled end. The bolt is spring loaded but can be drawn back by operating the lock trim. When the door is closed, the latchbolt projects into a hole in the strike, which holds the door in a closed position.

- Lock case/lock body-the portion of the lock that houses the inner workings of the lockset. The ability to hand the lock or adjust the function is usually located here.

- Deadbolt– provided with certain mortise lock functions, the deadbolt is thrown into the strike by action of the lock mechanism initiated by a key or thumbturn. The deadbolt along with the latchbolt, secures the door.

- Auxiliary Latch or Deadlatch-a supplementary latch which, when the door is closed, is pressed against the strike and prevents the latchbolt from being pushed in by end pressure.

- Scalp plate/lock front/armor plate/edge plate-the exposed surface of a mortise lock as seen in the edge of a door.

- Strike– a metal plate mounted to the door frame, or inactive leaf of a pair of doors, to receive the projected bolt or latch of a lock. Standard commercial strikes are typically 4 7/8”.

Contact our technicians at LaForce for additional tips or to order parts!

Follow Us