The shipping process for our pre-installed doors is getting a new look thanks to sustainable honeycomb spacers! In our efforts to continue to be environmentally friendly, LaForce has partnered with Green Bay Packaging to change the materials we use to ship our products from polystyrene to 100% recyclable paper.

When shipping doors with pre-installed hardware, we have traditionally used spacers made of extruded polystyrene foam (EPS), otherwise known as Styrofoam. These spacers protected the doors from damage during transit. Unfortunately, polystyrene is not biodegradable, is harder to recycle, can cause harmful air pollutants, and is considered a non-renewable resource because it is oil-based.

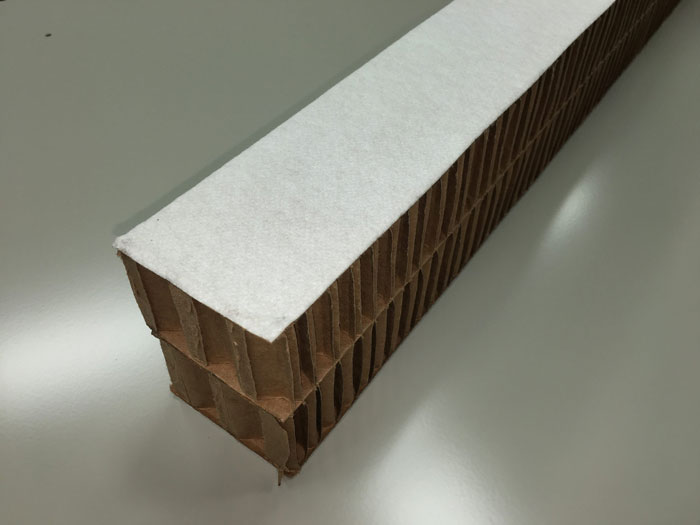

To reduce our impact on the environment, we have switched to paper fiber honeycomb spacers. These spacers are made of renewable and sustainably forested wood fibers that are biodegradable and 100% recyclable given the current recycling infrastructure. The process of making this sustainable packaging solution also emits an estimated 25% less greenhouse gas than our old spacers. With their honeycomb design and soft tissue covering, our new spacers still offer the same cushion and shock absorption needed to protect our doors during shipping. So, although our materials may look a little different, there is no need to worry about the integrity of your product.

We are proud to be working with Green Bay Packaging to implement this sustainable packaging solution and continue reducing our impact on the environment. In addition to these spacers, LaForce recycles almost 100% of all our wood pallets, cardboard, aluminum, and scraps (such as steel, stainless steel, brass, and bronze). With our pre-installation service, we install hardware onto doors prior to shipping, which allows us to recycle all packaging materials and reduce waste at the construction site.

If you’re interested, you can learn more about how we strive for sustainability. And if you are interested in talking to a LaForce expert about how we can help you with your next project, contact us today!

Follow Us